The Waste Robotics Revolution in Construction and Demolition Waste Management

In this article, we discuss the benefits of Waste Robotics' technology for addressing the challenges of sorting Construction and Demolition waste (C&D).

- Waste Robotics revolutionizes the management of C&D waste with innovative sorting technology.

- Waste Robotics' robotic arms and grippers are designed to handle up to 25 kg of material, improving sorting efficiency.

- The technology is highly modular, enabling customized configuration to suit the specific needs of sorting centers.

- The adaptability of the sorting algorithm means it can handle a wide variety of objects, and change quickly to meet changing needs.

- Dynamic speed control adjusts automatically to maximize stream purity and minimize risk.

- Favorable legislative frameworks are encouraging the adoption of robotic technology to reduce C&D landfills.

- By adopting Waste Robotics' technology, companies contribute to sustainability, reducing environmental impact and preserving natural resources.

In an ever-changing world where waste management is becoming increasingly crucial, companies are looking for innovative solutions to the challenges posed by C&D waste. It's against this demanding backdrop that Waste Robotics, a pioneering company in the recycling sector, stands out with a revolutionary solution capable of redefining the way C&D waste is sorted and managed. In this article, we take a deep dive into Waste Robotics' advanced technology and explore how it meets the needs of CIW sorting center operators in USA, Canada, France, Belgium, Switzerland, Luxembourg and beyond.

Cutting-edge technology from Waste Robotics

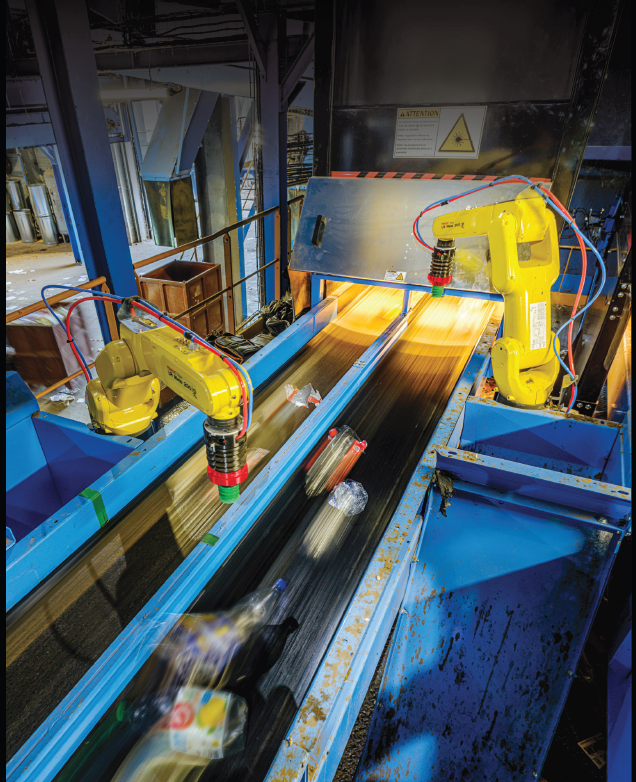

1. High-tech robotic arms and grippers:

One of the major assets of Waste Robotics' technology lies in the use of robotic arms equipped with state-of-the-art grippers that require very little maintenance, thanks to the use of highly resistant and repairable parts. These arms have been designed to revolutionize CIW sorting by considerably improving efficiency. They are capable of lifting loads of up to 25 kg of material, guaranteeing precise and efficient waste handling. This capability makes sorting heavy, bulky objects a breeze, ensuring better recovery of recyclable materials.

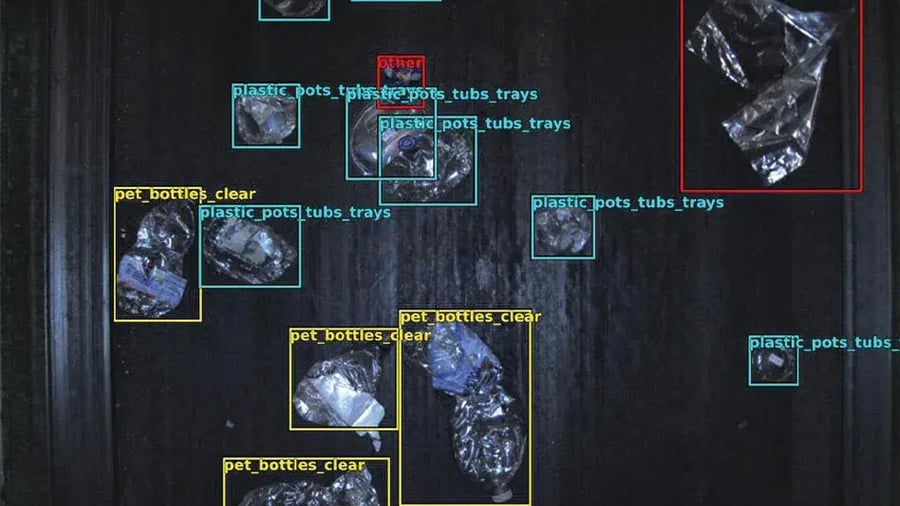

2. Unrivalled adaptability of the sorting algorithm

Another major strength of Waste Robotics' technology is its ability to adapt in real time to changing sorting needs. It can rapidly modify its sorting algorithm to respond to a wide variety of objects, a crucial feature in an environment where waste flows are constantly diversifying. Waste Robotics thus offers a tailor-made solution for optimizing sorting.

.jpg?width=1762&height=863&name=hyperspectral-C%26D%20(1).jpg)

3. Modularity and Customized Sorting Line Configuration

Waste Robotics recognizes the diversity of needs within CIW sorting centers. That's why our technology features exemplary modularity and adaptability to the specific requirements of each center. This gives operators the freedom to customize configurations to suit their particular waste stream, promoting optimum efficiency. This flexibility ensures more efficient resource management and more precise sorting.

4. Dynamic Speed Control

Waste sorting is not a static process, and Waste Robotics excels in just this area. Its system features dynamic speed control that automatically adjusts to the waste stream. In fact, robotic technology allows the use of 1.8m (5.9 ft) wide conveyors. When a large quantity of material has to be sorted, the system slows down to ensure optimum precision. On the other hand, when the purity of the flow improves, it speeds up to maintain high productivity. This automatic adjustment capability helps reduce risk and maximize recovery of recyclable materials.

Legislation supporting the adoption of Robotic Technology

Countries and regions such as France, Belgium, Switzerland and Luxembourg have recognized the imperative of reducing non-hazardous industrial waste and promoting recycling. In response to these major environmental challenges, many jurisdictions have established legislative frameworks encouraging the adoption of innovative technologies such as those proposed by Waste Robotics.

These legislative frameworks set ambitious recycling targets, stimulating improvements in recovery rates for recyclable materials contained in HIW. By opting for cutting-edge technology such as that offered by Waste Robotics, sorting centers are positioning themselves to meet these targets and help reduce the volume of waste sent to landfill.

Positive Environmental Impact

Legislative frameworks also emphasize the need to reduce the environmental impact of CIW management operations. Robotic sorting solutions help reduce energy consumption, greenhouse gas emissions and non-recyclable waste. They help preserve natural resources by encouraging the reuse of existing materials.

Conclusion

Waste Robotics' innovative technology offers an adaptable and effective solution to the ever-changing challenges faced by operators of CIW sorting centers. Thanks to its robotic arms, modularity, sorting adaptability and dynamic speed control, it improves CIW management while reducing environmental impact.

What's more, incentive-based legislative frameworks are encouraging companies to commit to sustainability, to help reduce waste and preserve the environment.

It's time for companies in the CIW sector in France, Belgium, Switzerland, Luxembourg and far beyond to explore the benefits of Waste Robotics' technology and play a key role in building a cleaner, more sustainable future.

If you're a company or sorting center interested in the benefits of Waste Robotics' technology, we invite you to fill the contact form below to find out more about how we can help you optimize your C&D sorting process and contribute to more responsible waste management.

Subscribe to Our Newsletter

Millennium Recycling and Waste Robotics Collaborate to Achieve a 55% Increase in Recovery Rates